New materialsNew material

The use of alloy material can increase the toughness and wear resistance of the product, improve the product quality and reduce the noise.

The use of alloy material can increase the toughness and wear resistance of the product, improve the product quality and reduce the noise.

Breaking through the traditional powder metallurgy process, adopting the alloy one-time forming technology and fully automatic integrated production.

Using one-time molding technology, fully automated production, improve efficiency, reduce manufacturing costs.

It has obtained more than 20 patent certificates, and has a professional R & D team to continuously innovate and improve the market competitiveness of enterprises

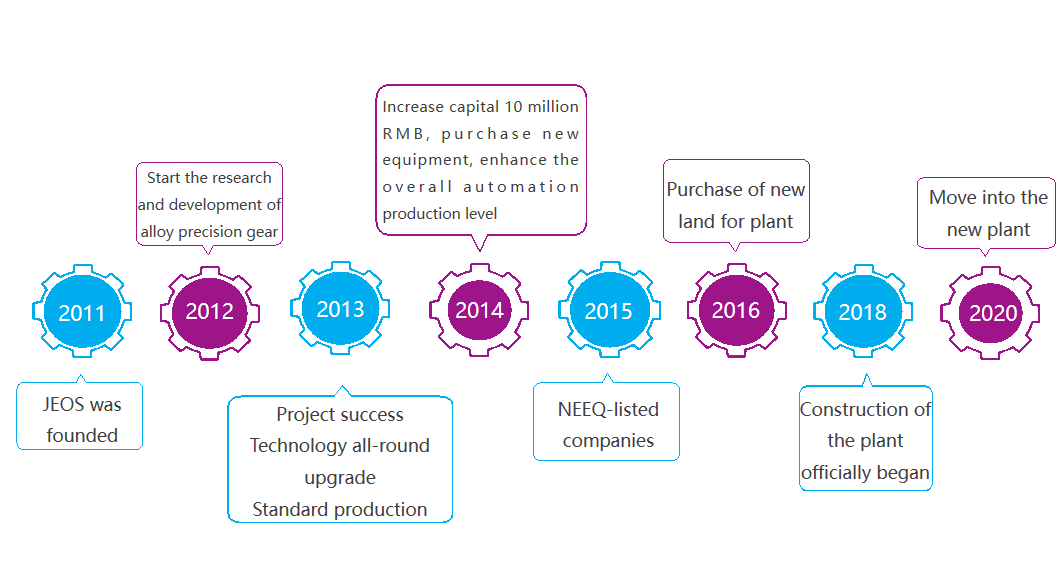

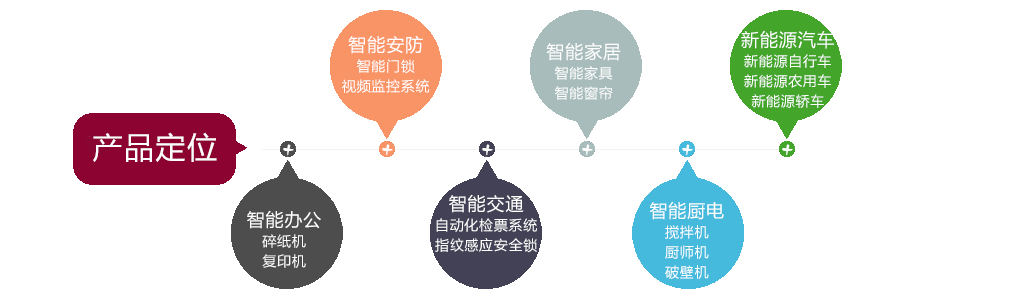

JEOS is a professional set of precision zinc alloy, aluminum alloy die-casting and all kinds of metal gear, integral gear box integrated manufacturing enterprises,which was founded in 2011 and located in the “World Manufacturing Center” of Dongguan City. JEOS has more than 20 88T-800T die casting machine, imported CNC machining center, and a number of post-processing equipent, from mold development to electroplaing, oil injection, powder injection and other surface treatment are completed by the JEOS. JEOS main industries involved in the production include: Kitchen appliances, intelligent security, intelligent home, office supplies, communication electronics, new energy vehicles, electric tool, and hardware die-casting,gear, integral movement products,etc. JEOS has passed the ISO9001quality management system and has a complete set of testing equipment, such as: 3 dimensional, 2.5 dimensional, material composition detector,colorimeter, film thickness detector hardness tester and etc. JEOS insist adhere to business philosophy of the “integrity as the principle, innovation for development, win-win as goal". The products are mainly sold to Guangzhou, Shenzhen, Dongguan, Zhuhai, Foshan, Hangzhou, Suzhou, Shanghai and other places.

In 2012, the development of alloy precision gears was fully started, a

新闻资讯2019-04-08

The gearbox reducer is in high-speed operation, so some friction canno

新闻资讯2021-03-26

The gearbox reducer is in high-speed operation, so some friction canno

新闻资讯2021-03-26

The gearbox reducer is in high-speed operation, so some friction canno

新闻资讯2021-03-26

9 years of industry experienceFounded in 2011, the company is a comprehensive enterprise specializing in precision zinc alloy and aluminum alloy die casting and machining

Company missionTo provide customers with high quality products and services with high cost performance, and continue to innovate in technology and management, so that the company can become a truly world-famous enterprise...

Company management philosophyTo achieve the benefit sharing among employees, customers, shareholders and enterprises with "market-oriented, quality as guarantee and innovation as fundamental", it has become the world's best outstanding enterprise of "integrated driver" manufacturing

Core values of the companyThe company has always adhered to the "integrity as the principle, innovation for development, win-win" business philosophy!

Core competitiveness of the companyUsing the patent technology, we can tailor-made "integral transmission" products with high cost performance and best precision performance, and provide one-stop service

Company visionTo become the world's best quality "integrated driver" manufacturing outstanding enterprises

24-hour fast service responseJieaosi gold customer service 24 hours online for your service, instant response, troubleshooting, 24 hours to quickly solve problems.

Research and development of alloy precision gearThe R & D of the new project has been successful, and the related process has been upgraded to form standard production

Enterprise honorPatent certificate, has obtained more than 20 patent certificates, has a professional R & D team, continuous innovation, improve the market competitiveness of enterprises

Don't worry about good productsBreaking through the traditional powder metallurgy process, adopting alloy one-time forming technology, fully automatic integrated production, using alloy materials, increasing product toughness and wear resistance, improving product quality, reducing noise, adopting one-time forming technology, fully automatic production, improving efficiency and reducing manufacturing cost

One stop planThe company has more than 20 sets of 88t-600t die-casting machines, imported CNC machining center, automatic production equipment and a number of post-processing supporting equipment, etc. from mold development to electroplating and spraying surface treatment, the company completes the whole process

quality management systemThe company has passed the ISO9001 quality management system and has a complete set of testing equipment, such as: 3-dimensional, 2.5-dimensional, material composition detector, color difference meter, film thickness detector, hardness tester, etc.